Calcium Silicate Insulation Boards are made from calcium and silicon and are designed for high-temperature and fire-resistant applications.

They are widely used for pipes, thermal equipment, power plants, petrochemical units, and foundries as thermal insulation and as back-up lining for industrial furnaces.

These boards are designed to provide high structural strength and can operate in systems up to 1200°F. Made from hydrous calcium silicate, they are inorganic, noncombustible, and meet standard physical and thermal property requirements, while offering corrosion resistance on exposed surfaces of pipes and equipment.

Calcium Silicate Boards are available in preformed block and preformed pipe forms and are suitable for chemical plants, refineries, steam power plants, and other industrial sectors requiring reliable fire and thermal protection.

AVAILABLE GRADE & SIZES

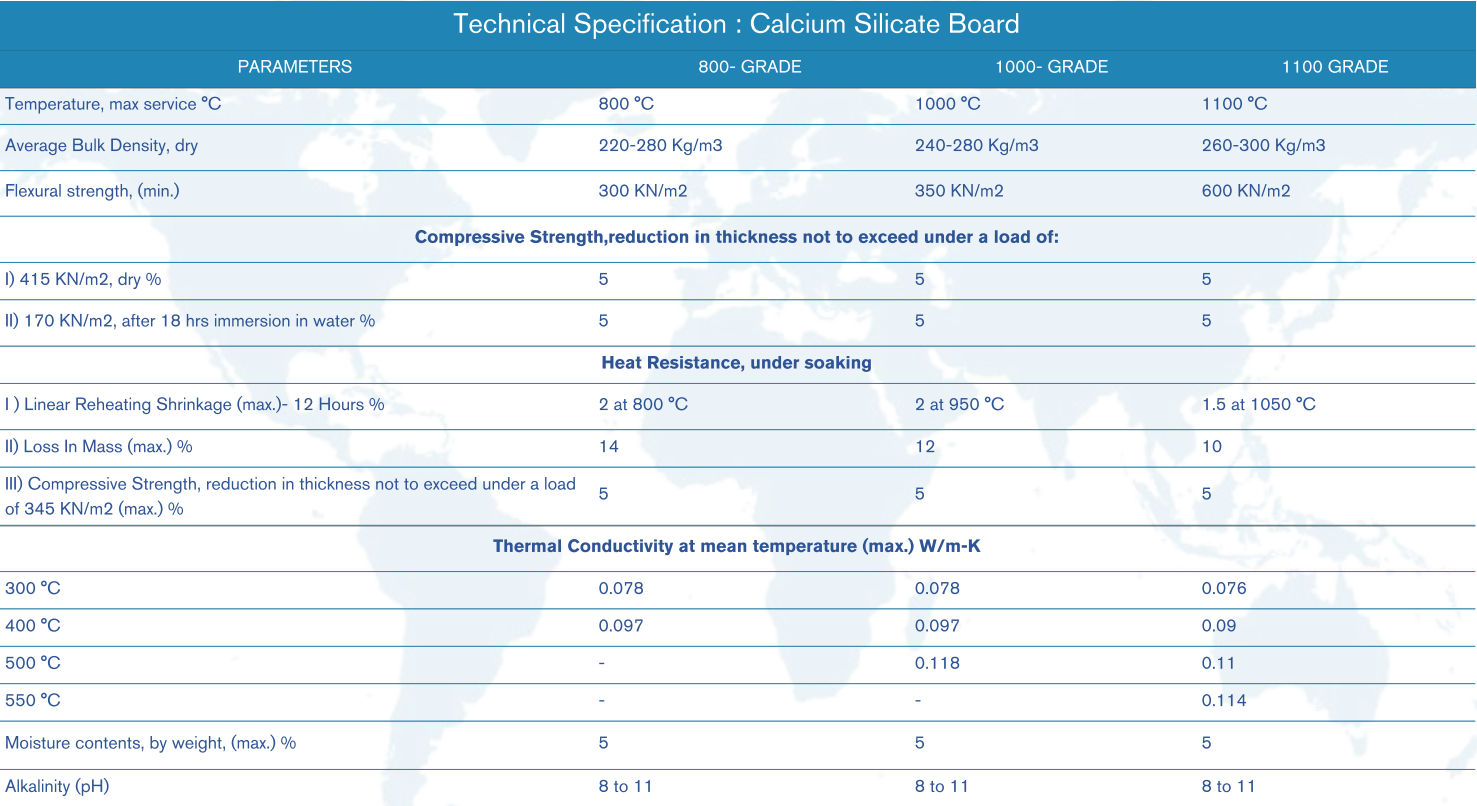

GRADES

800 °C Temeprature

1000 °C Temeprature

1100 °C Temeprature

Available Sizes (With 25,40,50,65,75,100 mm Thickness)

1000×500 mm

1000×610 mm

900×600 mm

500×150 mm

600×150 mm

450×150 mm

* Special sizes and thicknesses can be manufactured upon request.