AVAILABLE GRADE AND SIZES

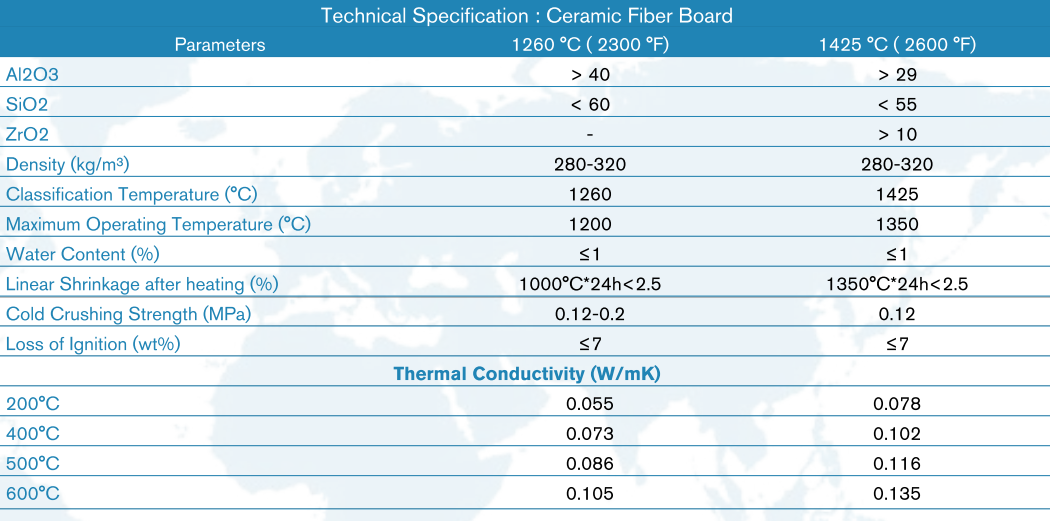

Grade (°C) : 1260 °C & 1425 °C

Thickcness (mm) : 10 mm to 100 mm

Standard (Width x Length) mm: 500×1000 mm, 600×1000 mm

Density (Kg/m3): 320-384 kg.m3

Packing

Thickcness (12 mm) = 12 PCs/Box, Thickcness (25 mm) = 06 PCs/Box

Thickcness (50 mm) = 04 PCs/Box, Thickcness (100 mm)= 02 PCs/Box

CHARACTERISTICS

- Excellent insulating performance.

- Excellent thermal stability.

- Excellent strength and hardness.

- Resistance to thermal shock.

- Good machinability.

- Low thermal conductivity, sound transmission, and heat storage.

- Uniform density and excellent resistance to thermal shock and chemical attack.

- Resists penetration by molten aluminum and other non-ferrous metals.

- Permits fast thermal cycling without cracking or spalling.

- Excellent rigidity and modulus of rupture make the boards strong and self-supporting, yet relatively lightweight and easy to cut or machine.